To thrive in today’s competitive global market, industries must constantly pursue higher efficiency and increased production capacity without compromising quality.

Achieving this elevation requires a multi-pronged approach that integrates cutting-edge technology, meticulous operational planning, and a strong commitment to quality control.

Mere incremental improvements are no longer sufficient; businesses must adopt transformative strategies that eliminate waste, minimise downtime, and leverage advanced infrastructure.

By strategically focusing on asset reliability, quality assurance, and workforce upskilling, industries can ensure sustained growth, reduce operational costs, and solidify their position as market leaders.

Adopting Industrial Automation and Digitalisation

The most powerful driver of modern production efficiency is the strategic adoption of automation and digitalisation. Integrating smart factory technologies, such as robotics, Artificial Intelligence (AI), and the Internet of Things (IoT), allows for continuous, high-speed production with minimal human error.

Implement advanced Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) to create a single, unified view of the production floor, inventory, and supply chain.

This real-time data visibility enables predictive maintenance and immediate process adjustments, significantly boosting throughput and material usage efficiency.

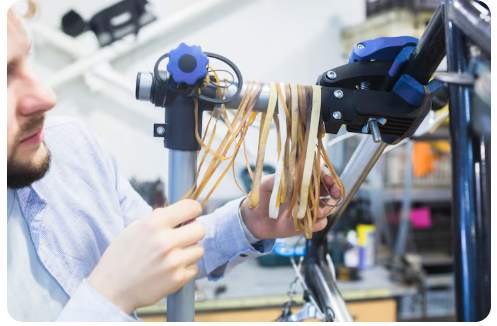

Ensuring System Reliability with Timely Conveyor Repair

In many industrial and manufacturing settings, material handling systems like conveyors are the backbone of the entire production line. A breakdown in this critical infrastructure can halt all operations, resulting in massive, costly downtime.

A proactive approach to system reliability necessitates securing expert and timely conveyor repair services. Regular preventative maintenance, lubrication, and inspection of belts, motors, and sensors should be standard practice.

By investing in professional conveyor repair and maintenance, industries can drastically reduce unscheduled stops, ensuring a consistent and smooth flow of materials that directly translates to higher production output.

Upholding Quality Standards with Cleanroom Certification

For industries dealing with sensitive products, such as pharmaceuticals, microelectronics, or aerospace components, maintaining a strictly controlled environment is paramount.

Regular cleanroom certification is essential to guarantee that controlled facilities meet international standards (like ISO 14644).

Certification involves rigorous testing of air particulate counts, air flow velocity, pressure differentials, and filtration integrity.

By consistently upholding the highest level of cleanliness verified through cleanroom certification, manufacturers protect product quality, minimise contamination risks, and comply with regulatory requirements, which is crucial for market acceptance and reputation.

Implementing Lean and Six Sigma Methodologies

Efficiency is a culture, not just a set of tools. Adopting Lean manufacturing principles focuses on the systematic elimination of waste in all forms—overproduction, waiting time, defects, and excess inventory.

Complementary Six Sigma methodology aims to reduce process variation, ensuring that production output is near-perfect (fewer than 3.4 defects per million opportunities).

Training teams in these continuous improvement methods empowers employees at every level to identify bottlenecks and suggest improvements, fostering a culture where efficiency gains are constantly sought and sustained.

Strategic Investment in Workforce Upskilling

As production systems become more complex and automated, the skills gap among the workforce must be addressed. Industry progress requires a strategic investment in upskilling and retraining programs that focus on digital literacy, robotics maintenance, and data analysis.

A highly skilled, adaptive workforce is essential for managing and optimising advanced machinery, interpreting performance data, and troubleshooting complex issues quickly.

This investment in human capital ensures that the workforce is a competitive asset, not a constraint on production capacity.