What Are the Best Practices in Temporary Structure Engineering?

Posted On

Posted On

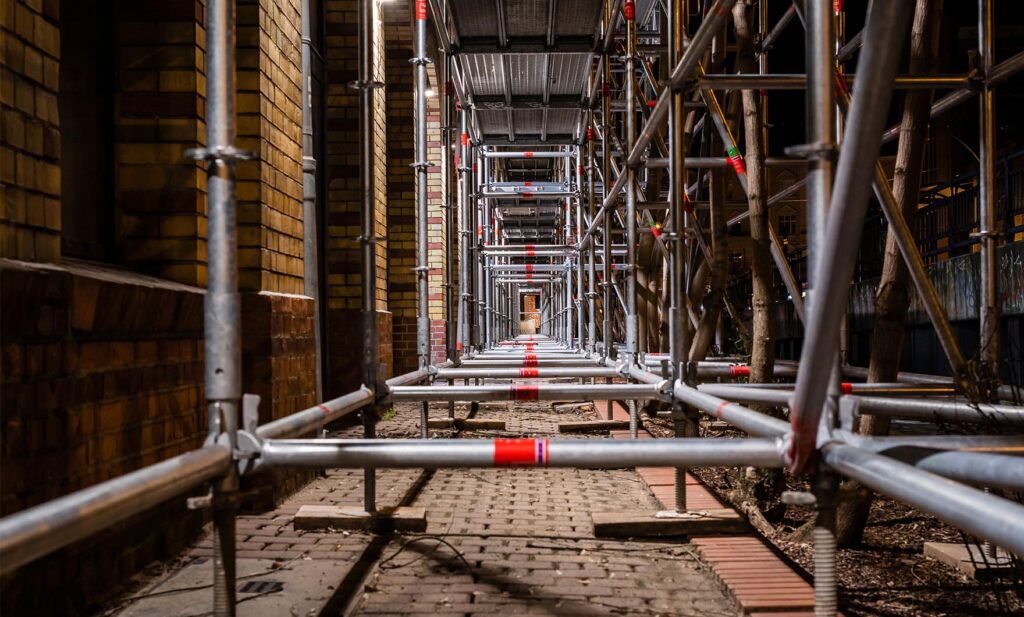

In every major construction project, temporary structures — such as scaffolding, shoring, and formwork — play a critical role in keeping workers safe and ensuring the permanent structure is built accurately and efficiently. While these systems are designed to be temporary, the engineering behind them must be as precise and reliable as any permanent structure.

That’s where the expertise of temporary structure engineers becomes indispensable. They ensure that every scaffold, support frame, or bridge platform is strong enough to handle dynamic loads, harsh weather, and demanding construction schedules — all while maintaining safety and compliance.

Leading firms like NadeauSDM temporary structure engineering follow a set of proven best practices that combine technical precision, safety, and innovation. These best practices define the standards for quality and reliability in modern temporary works.

Let’s explore these principles in detail.

1. Conduct a Comprehensive Site Assessment

Every successful temporary works design begins with a thorough site investigation. Before engineering begins, professionals assess:

- Soil and ground conditions.

- Load-bearing capacity and settlement risk.

- Weather exposure and drainage.

- Surrounding structures and utilities.

Understanding the environment helps engineers design temporary systems that are stable, safe, and perfectly suited to the site’s unique challenges.

2. Define Clear Design Objectives

Temporary structure engineering is never one-size-fits-all. Every project must start with defined goals based on the construction sequence, site conditions, and duration.

Key objectives should include:

- Supporting specific loads (live, dead, and dynamic).

- Providing safe worker access.

- Facilitating efficient construction without interference.

- Allowing easy removal once permanent structures are complete.

Clear goals ensure the design aligns with both the project timeline and safety requirements.

3. Prioritize Safety from the Start

Safety is the cornerstone of temporary works engineering. From concept to completion, every design decision should mitigate potential hazards such as collapse, overloading, or worker falls.

Engineers achieve this by:

- Incorporating redundant load paths for stability.

- Designing for worst-case environmental conditions.

- Including safe access points for assembly and maintenance.

- Following international safety standards like OSHA, Eurocode, and CSA.

The safest temporary structures are those that anticipate — and eliminate — potential risks before they arise.

4. Use Advanced Modeling and Analysis Tools

Modern engineering relies on technology for precision. Advanced modeling tools allow engineers to simulate and test designs before implementation.

Common tools include:

- Building Information Modeling (BIM): Creates 3D visualizations of temporary and permanent structures for coordination.

- Finite Element Analysis (FEA): Analyzes stress, strain, and deflection under different loads.

- Digital twins: Enable real-time monitoring and performance prediction.

These tools improve efficiency, accuracy, and collaboration among project stakeholders.

5. Plan for Integration with Permanent Works

Temporary structures must complement — not conflict with — the permanent construction. Engineers ensure their systems:

- Do not obstruct ongoing work.

- Safely transfer loads between temporary and permanent components.

- Are removed without damaging the finished structure.

Integration planning avoids costly modifications and keeps the construction process seamless.

6. Perform Accurate Load and Stability Calculations

Temporary works face complex load combinations, including:

- Dead loads: The self-weight of the structure.

- Live loads: Workers, materials, and equipment.

- Wind and seismic forces: Environmental stresses.

- Dynamic loads: Machinery and vibrations.

Each load must be carefully calculated and distributed. Engineers use factor-of-safety multipliers to ensure structures perform safely under all possible conditions.

7. Ensure Quality Materials and Components

The strength of any temporary structure depends on the materials used. Engineers should:

- Specify certified, high-grade materials that meet local codes.

- Inspect all equipment (tubes, couplers, beams) for wear and corrosion.

- Use modular and reusable components to promote sustainability.

Quality assurance in materials prevents premature failure and enhances both safety and cost-efficiency.

8. Implement Rigorous Inspection and Maintenance Schedules

Temporary structures are subject to constant stress. Regular inspection and maintenance are vital to prevent small issues from becoming major failures.

Best practices include:

- Daily on-site checks by qualified personnel.

- Scheduled engineering inspections after weather events.

- Load testing before use.

- Immediate repair or replacement of damaged elements.

This proactive approach ensures long-term reliability throughout the construction phase.

9. Maintain Detailed Documentation and Records

Transparency and traceability are key to accountability. Engineers document every phase of the project, including:

- Design drawings and calculations.

- Risk assessments and safety plans.

- Inspection reports and modifications.

- Load certifications and test results.

This documentation not only ensures compliance but also provides critical reference material for audits and future projects.

10. Train and Supervise On-Site Personnel

Even the best-engineered temporary structure can fail if used incorrectly. That’s why comprehensive training and supervision are non-negotiable.

Best practices include:

- Providing installation manuals and training sessions.

- Supervising assembly and dismantling by qualified professionals.

- Enforcing compliance with safety procedures.

- Encouraging open communication between workers and engineers.

A well-trained crew ensures that the system functions exactly as designed.

11. Conduct Risk Assessments and Contingency Planning

Before installation, engineers perform risk assessments to identify potential hazards. This includes evaluating structural failure scenarios, weather impacts, and material limitations.

They then create contingency plans such as:

- Backup supports or bracing systems.

- Emergency evacuation routes.

- Load reduction strategies during high winds or heavy rainfall.

By preparing for the unexpected, engineers minimize downtime and prevent accidents.

12. Foster Collaboration Between Disciplines

Temporary structure engineering involves close coordination with architects, contractors, and permanent works designers. Collaboration ensures:

- Alignment between temporary and permanent load paths.

- Efficient construction sequencing.

- Fewer design conflicts and rework.

Regular communication keeps the entire team informed and the project running smoothly.

13. Adapt Designs to Environmental Conditions

Temporary structures must withstand real-world forces such as:

- Extreme weather (wind, snow, or temperature changes).

- Ground movement or settlement.

- Nearby vibrations from traffic or equipment.

Engineers adapt their designs with additional anchoring, wind bracing, and flexible joints to maintain stability even in unpredictable environments.

14. Embrace Sustainability and Reusability

Sustainability is a growing focus in temporary works. Engineers can reduce environmental impact by:

- Designing modular systems for reuse across projects.

- Selecting recyclable materials like steel and aluminum.

- Minimizing waste through precision fabrication.

- Implementing eco-friendly coatings and finishes.

Sustainable practices align with green building standards and reduce long-term project costs.

15. The Role of Expert Firms in Best Practice Implementation

Successfully implementing these best practices requires expertise, precision, and field experience. Companies like NadeauSDM temporary structure engineering combine decades of engineering knowledge with advanced tools and strict safety protocols to deliver reliable, compliant, and efficient temporary works.

Their engineers focus on:

- Customized design solutions for each site.

- Compliance with regional and international standards.

- Advanced modeling for safety verification.

- Close collaboration with contractors and clients.

By adhering to industry-leading best practices, they ensure temporary works perform flawlessly under even the most demanding conditions.

Final Thoughts

Temporary structures might be short-lived, but their importance in construction is monumental. A single miscalculation can compromise an entire project — which is why temporary structure engineering demands precision, planning, and professionalism at every stage.

By following best practices such as rigorous analysis, proactive inspection, and collaborative design, engineers create systems that are safe, efficient, and sustainable.